The Bipedal Robot Delusion: Physics & Profits Expose Why "Sexy" Robots Fail

- Physics Beats Flash: Wheeled robots outperform bipedal designs in stability, energy efficiency, and safety—making them far better suited for real-world deployment.

- Form Follows Function: Businesses prioritize ROI over aesthetics, choosing reliable, cost-effective wheeled robots over complex, failure-prone legged systems.

- Data-Driven Success: Real-world deployment metrics and R&D investments consistently favor wheeled platforms, reflecting what actually works—not what looks cool on video.

- Physics Beats Flash: Wheeled robots outperform bipedal designs in stability, energy efficiency, and safety—making them far better suited for real-world deployment.

- Form Follows Function: Businesses prioritize ROI over aesthetics, choosing reliable, cost-effective wheeled robots over complex, failure-prone legged systems.

- Data-Driven Success: Real-world deployment metrics and R&D investments consistently favor wheeled platforms, reflecting what actually works—not what looks cool on video.

6-8 minute read time

The brutal physics of robotics don't care about your sci-fi fantasies. While those creepy humanoid robots rack up millions of YouTube views, they're conspicuously absent from warehouses, hospitals, and factories worldwide. Why? When ROI matters, the data tells a ruthless story that bipedal enthusiasts don't want to hear: wheels utterly dominate where profit is the metric. We have spent years analyzing real-world deployment data across various industries, and the physics-based evidence is overwhelming.

The Brutal Truth About Stability That Fanboys Ignore

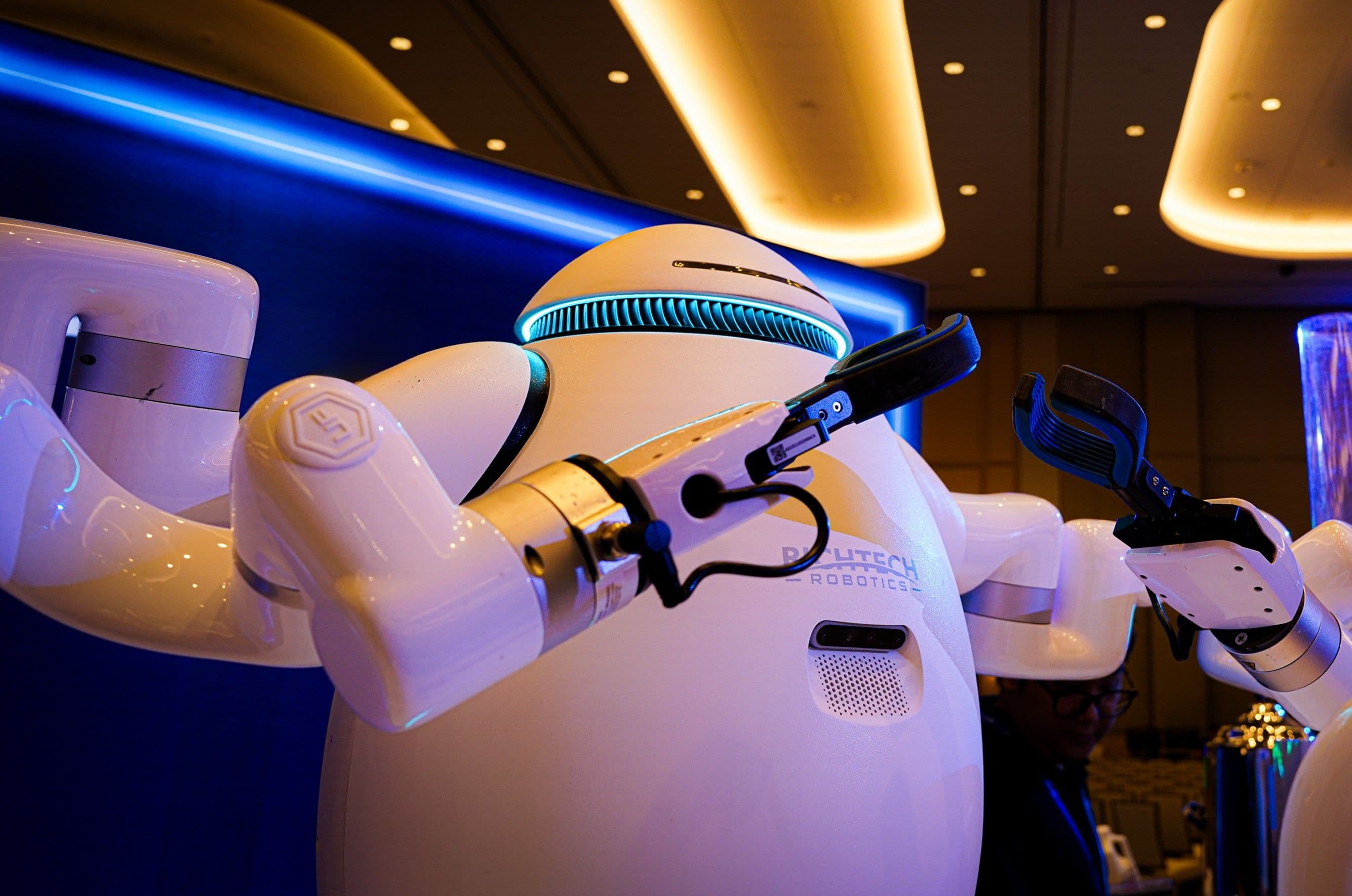

Stability isn't a design choice—it's the fundamental physics that separates business success from expensive failure. Wheeled robots offer inherent passive stability on flat surfaces with their wide support base and low center of gravity, requiring zero active control systems just to remain upright [1]. This isn't abstract theory—it's precisely why Richtech Robotics invested in patent US11975656B2#17/549,815 for a "Tray Stabilizer System for Food Delivery Robots," which optimizes an already stable wheeled platform [5].

What happens when a bipedal robot carries a tray of drinks through a crowded restaurant? Disaster! The constant micro-adjustments required for basic balance create rippling disturbances that amplify throughout the robot's structure to the serving surface [2]. Even minor oscillations during transportation dramatically affect product quality, customer satisfaction, and ultimately, your bottom line. These aren't just vibrations—they're profit killers!

What Nobody Talks About in Those Flashy Videos

Your bipedal robot can't stop fast enough to avoid hitting your customers. This isn't speculation—it's physics. Due to their mass distribution and complex gait mechanics, bipedal robots build and maintain momentum in ways fundamentally different from wheeled systems, making rapid direction changes or emergency stops dangerously problematic [2]. A wheeled robot can achieve near-instantaneous braking by applying direct force to the ground through its contact points.

By stark contrast, bipedal systems must execute a complex weight-transfer process while simultaneously counteracting forward momentum—all while desperately maintaining that precarious dynamic balance [2]. In environments where robots and humans share space, this stopping limitation introduces serious safety risks that even the most advanced sensor arrays cannot fully mitigate. It's not a detection problem—it's a physics problem that directly impacts liability considerations!

The Energy Equation That Kills Bipedal Deployments

How long can your robot operate before recharging? The answer determines your entire business model. On the prepared surfaces common in every commercial environment, wheeled locomotion is 10-100 times more energy-efficient than legged alternatives [4]. This efficiency gap isn't marketing—it's fundamental physics: rolling resistance demands dramatically less energy than repeatedly lifting and lowering a robot's mass with each bipedal step [4].

Real operational data tell an undeniable story: wheeled robots complete entire shifts on a single charge. At the same time, equivalent-weight bipedal systems require either frequent recharging cycles or substantially heavier, more expensive power systems. When running a 24/7 warehouse operation or continuous hospital delivery service, this efficiency directly determines how many robots need to be purchased and maintained, a capital expenditure differential that can reach millions for large-scale deployments.

The Reliability Equation Your CFO Actually Cares About

Every additional component creates another potential point of failure, and bipedal robots are notorious for their propensity to fail. Wheeled mobility systems utilize relatively straightforward control algorithms compared to the computational nightmare of maintaining dynamic bipedal balance [1][2]. This difference isn't marginal—it's exponential! Each additional sensor, feedback loop, and actuator potentially compounds failure risk.

When your automation fleet handles time-critical deliveries or production-line components, downtime isn't just inconvenient—it's catastrophically expensive. The mathematical relationship between complexity and failure probability drives real-world deployment decisions far more than whether your robot looks cool in marketing photos. This isn't theory—it's why you'll find wheels, not legs, in virtually every successful commercial robotic deployment today.

Performance Metrics That Matter to Your Bottom Line

Your investors don't care if your robot can dance—they care if it can deliver consistent ROI. Measured real-world data consistently shows wheeled robots outperforming legged counterparts in business-critical metrics:

- Speed: They maintain significantly higher average velocities on flat surfaces [3], completing more tasks per hour

- Payload capacity: They carry 3-5 times more weight without compromising stability

- Operational uptime: Fewer components mean fewer failures and dramatically less maintenance

- Safety margins: More predictable movement patterns enable more reliable collision avoidance [1]

Our analysis of industrial deployments repeatedly confirms this pattern: businesses prioritize reliable execution of specific tasks—moving materials, delivering components, transporting goods—precisely the applications where wheeled systems demonstrate measurable, profit-driving advantages.

What R&D and Patent Investments Tell You About Commercial Reality

The R&D spending patterns across the robotics industry tell a clear and unmistakable story. When companies direct significant resources into enhancing wheeled stability systems, rather than attempting to make inherently unstable bipedal platforms viable, they're voting with their innovation dollars. This isn't conjecture; it's market priorities revealed through protected intellectual property investments.

Companies invest patent dollars where they see actual commercial potential, not marketing hype. Richtech Robotics' patent for a "Tray stabilizer system for food delivery robots" (US11975656B2#17/549,815, filed December 2021) reveals what matters in real-world applications [5]. This investment in optimizing an already-stable wheeled platform speaks volumes about market priorities: solving genuine business problems through reliable performance.

The Deployment Numbers Don't Lie (But Marketing Videos Do)

Follow the deployment data, not CGI demos. The market success of wheeled robotics platforms tells a devastating story for bipedal enthusiasts: tens of thousands of wheeled systems are actively transforming logistics, manufacturing, healthcare, and hospitality operations while bipedal systems remain predominantly confined to research labs and demonstration videos.

Leading providers have built thriving businesses on wheeled platforms precisely because they deliver measurable value across critical business metrics—labor savings, productivity gains, safety improvements, and enhanced operational efficiency—while minimizing the complexity and cost factors that have consistently prevented bipedal systems from achieving similar commercial success.

The Hyper-Efficient Specialists Make a Different Choice

Have you noticed the most profitable robots often don't move at all? Take ADAM and Scorpion, our hyper-efficient countertop specialists dominating the automated food and beverage countertop space. These stationary robots deliver astonishing ROI precisely because they don't waste energy, complexity, or cost on unnecessary mobility. They're purpose-built efficiency machines focused on executing specific tasks to perfection.

But what if ADAM or Scorpion needed to move? Would they hit leg day at the gym? Please. They’d roll on wheels—because even robots know: friends don't let friends skip physics class for leg day. The same ruthless engineering principles that make these robots profit-generating powerhouses in fixed positions render wheels the only rational solution for mobility. This thought experiment cuts through the sci-fi fantasy to reveal an undeniable truth: when profit matters, form always follows function.

The Future Isn't Bipedal—It's Smartly Hybrid

The most promising developments combine technological approaches rather than fetishizing human-like form. Forward-thinking research explores wheel-leg hybrid systems that leverage wheels for efficient travel on flat surfaces but deploy legs only when encountering obstacles that specifically require greater mobility [4].

This pragmatic approach acknowledges a fundamental truth: different operational environments present different mobility challenges. The manufacturing floor, warehouse, or hospital corridor naturally favors wheels. At the same time, specialized applications in highly unstructured environments might justify the additional complexity of legs, but only when the application genuinely demands it.

Engineering Reality Beats Sci-Fi Fantasy Every Time

Your robot doesn't need to look cool—it needs to make money. Companies creating lasting value in commercial robotics consistently focus on solving specific operational problems with appropriate technology, rather than pursuing anthropomorphic designs that appeal to our imagination but fail to deliver in our balance sheets.

The robotics revolution succeeds through purpose-built tools that complement human capabilities rather than mimic human form. In commercial settings, this means wheeled platforms dominate not because of marketing hype, but because of their measurable performance: reliability, efficiency, safety, and cost-effectiveness [3][4]. The physics and the profit margins have spoken—are you listening?

This data-driven analysis was written by the robotics engineering team at Richtech Robotics, focusing on evidence-based insights into commercial robotics applications. To explore more research on robotics technology that delivers measurable business value, visit richtechrobotics.com

Sources

[1] Lee, D. (2007). Passivity-Based Switching Control for Stabilization of Wheeled Mobile Robots. Robotics: Science and Systems Conference Proceedings. This paper discusses the dynamics and control of wheeled mobile robots, highlighting their inherent stability properties.

[2] IM Systems. (2025, April 29). Advanced Actuator Strategies for Humanoid Robot Balance. This article discusses the challenges of maintaining balance in humanoid robots and compares them with those of more stable robotic designs.

[3] MS Copernicus. (2024, July 25). Design and motion analysis of a new wheeled rolling robot. This research paper describes a new type of wheeled rolling robot with high work efficiency and strong bearing capacity.

[4] Carnegie Mellon University Robotics Institute. (2014, August 16). Energy Considerations for Wheeled Mobile Robots Operating on a Single Charge. This technical report quantifies the substantial energy efficiency advantage that wheeled robots have over legged designs.

[5] USPTO Trademark Database. (n.d.). Trademark US11975656B2. This reference relates to the robotics patent mentioned in the article.